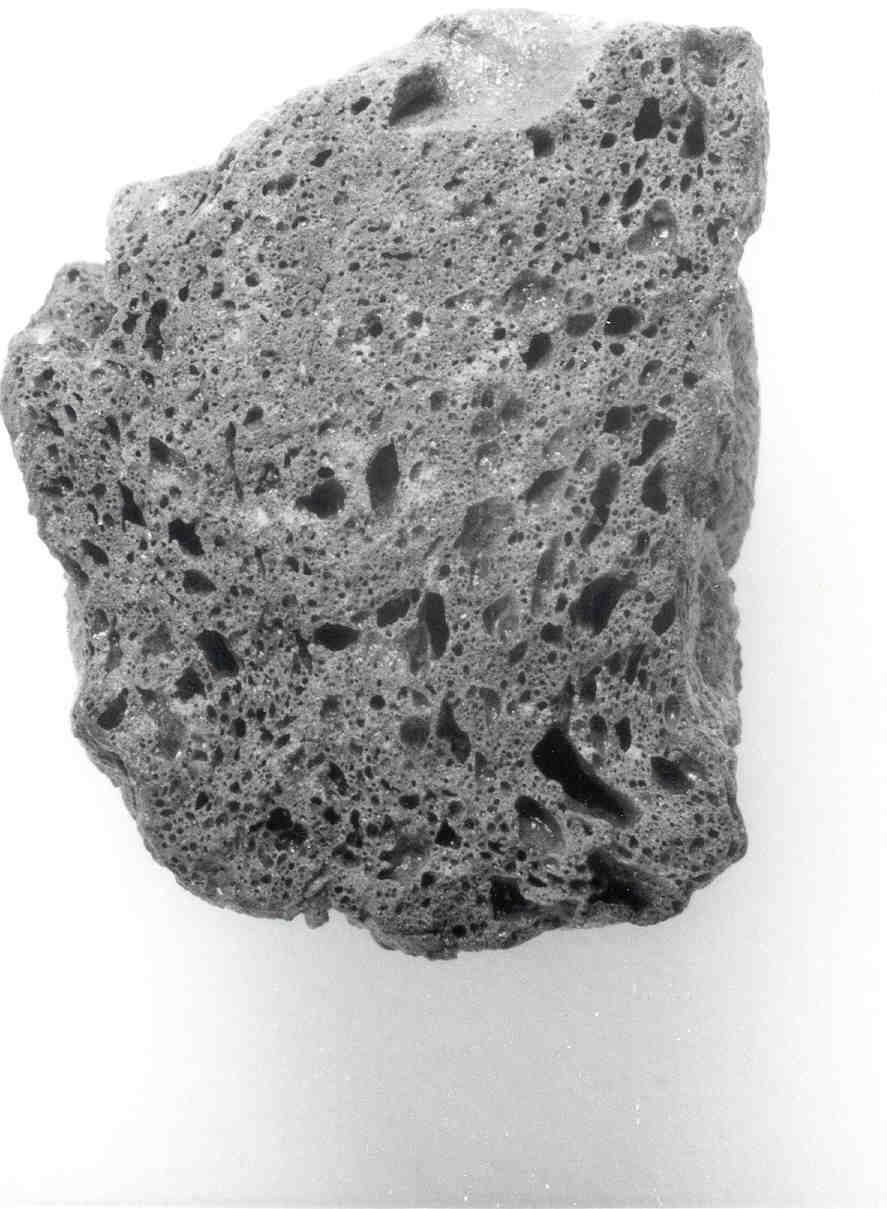

STALITE is a cost effective alternative to soil or heavyweight fills in geotechnical applications. Because of its lower weight, about 50% of normal weight fills, STALITE reduces lateral pressures so that more economical retaining walls can be utilized. Dramatic saving in transportation and placement costs can be achieved since trucks and other equipment can be safely filled to capacity without exceeding weight limits or increasing wear. STALITE’s high angle of repose provides very stable, long-lasting geotechnical fills, capable of supporting heavy, repetitive loads.

Geotechnical Applications:

Lightweight

Strong and durable

Stable (high angle of repose)

Chemically inert

Free draining

Consistent, controlled gradations

Economical to transport and place

STALITE is a cost effective alternative to soil or heavyweight fills in geotechnical applications. Because of its lower weight, about 50% of normal weight fills, STALITE reduces lateral pressures so that more economical retaining walls can be utilized. Dramatic saving in transportation and placement costs can be achieved since trucks and other equipment can be safely filled to capacity without exceeding weight limits or increasing wear. STALITE’s high angle of repose provides very stable, long-lasting geotechnical fills, capable of supporting heavy, repetitive loads.

Placing Method:

A. General:

Final compaction effort shall be determined in the field by the engineer. Place approximately uniform horizontal layers. Over-compaction should be avoided. Construction equipment, other than for compaction, shall not operate on the exposed lightweight fill.

B. Use of Vibratory Roller:

Horizontal layers should not exceed 12" loose thickness. Each layer shall be compacted using vibratory compaction equipment weighing no more than 12 tons static weight. The minimum recommended number of passes is two. Additional passes may be required and should be determined in the field by the engineer to insure

stability of the layer.

C. Use of Portable Vibratory Plate Compacting Machine:

Horizontal layers should not exceed 6" compacted. The minimum recommended number of passes is two. Additional passes may be required and should be determined in the field by the engineer insure stability of the layer. One pass requires vibration of the area covered by the plate for at least 10 seconds, before moving to the next adjacent location

Geotechnical Benefits for using stalite

- Cost Effective

- Water Insoluable

- Chemically Inert

- High Durability

- Increased Stability

- Free Draining

- Thermal Insulation

- Reduced Over Turning Forces

- High Internal Friction Angle (46 degrees)

- Reduced Dead Loads

- Acid Insoluable

- High Strength

- Controlled Gradations

- Controlled Settlement

- Reduced Lateral Forces

- Environmentally Friendly

Placement

• No Special Job Site Equipment Needed

• Readily Available

• Easy to Handle and Install

• Can Be Placed in Any Weather

• No Waiting Between Placing Lifts

• Lower Transportation Costs

• Less Wear on Equipment

• Easily compacted

Applications

• Slop Stabilization

• Subgrade Stabilization and Improvement

• Gas Ventilation for Landfills

• Thermal Insulation

• Landscape & Plaza Fill

• Fill Over pipelines and Conduits

• Fill Over Poor Soils and Marshlands

• Fill Behind Bulkhead & retaining walls

Engineers Design Table

Unit Weights of Stalite Lightweight Aggregate and Natural Granular Fill

Notes:In the table above, multiply by 0.157 to obtain kN/m3.

(a) Loose indicates minimum dry unit weight from ASTM D-4254,

and Compacted indicates maximum dry unit weight from the

Standard Compaction Test, ASTM D-4253.

(b) Surface dry weight after long-term absorption (STALITE =9%)

*STALITE is a low absorption aggregate. Unit weight after

long-term submersion is less than other lightweight aggregates.